The Nose Cone

Setting up Supersonic Airflow

One of the most important parts of Aussie Invader 5R is the design and construction of the nose cone. The nose cone sets up the airflow over the whole car, which is critical for the cars aerodynamic performance and stability.

When the car is running at subsonic speeds, a lot of what is going to happen to Aussie Invader’s airflow can be predicted with some certainty as there is aerodynamic data available on cars running in this speed range.

It is a lot more difficult to predict the actual airflow around the vehicle when it is travelling in the transonic speed range. Aerodynamicists remind us that some parts of the car are receiving subsonic airflow and some are receiving supersonic airflow

at the same time. This can result in turbulent airflow and general instability. Unfortunately, there is virtually no data available to any LSR teams on supersonic airflow close to the ground. Thrust SSC achieved mach 1.02, 763mph (1,223 km/h) but Thrust SSC only just made it through the sound barrier and the real fun starts when you exceed the speed of sound by a good margin.

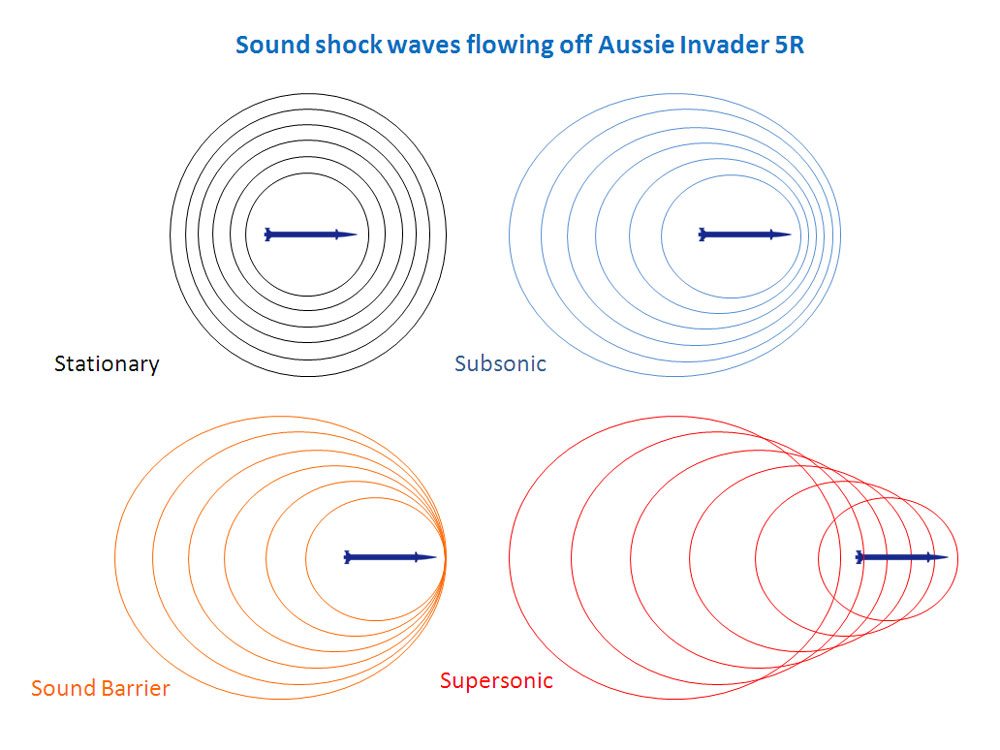

When Aussie Invader 5R reaches 1,000 mph it will have broken through the sound speed barrier, and will be travelling at close to 1.4 times the speed of sound, c (Mach 1.4). Since Aussie Invader 5R will be moving faster than the sound waves it creates, it actually leads the advancing wavefront. The car will pass by a stationary observer before the observer actually hears the sound it creates.

The “sonic boom” an observer will hear as it goes through the sound barrier and beyond is actually the sound of the shock waves crashing into each other.

Aircraft have travelled at supersonic speeds for over 60 years. However, the shock waves from an aircraft can dissipate in all directions, where as a car in contact with the ground is completely different and the shock waves reflected from the ground can potentially cause a lot of unwanted lift and drag issues.

Running CFD (computational fluid dynamics) will help to predict how a particular nose cone may perform against other designs. However, in all reality it will not determine every aspect of its performance, the safest and fastest nose cone will be determined with reference to data extracted from Aussie Invader’s preliminary speed trials. Methodical lift and stability testing over successively faster speeds will confirm a given nose profile’s ability to make record breaking runs.

Beyond the speed of sound, air acts more like water i.e. the air reacts as though it is very dense. Aussie Invader 5R’s nose will need to slice through the air and divert as much air to either side of the car as possible. In one sense, the nose cone must perform like the bow of a high speed boat and, as you can appreciate, a powerful boat with a poor bow design will not cut through the water and reach its potential. A good nose cone will reduce air travelling under the car.

However, at supersonic speeds, there will still be a large volume of high speed air which will induce shock waves which can unlike boat design where it is preferable for the craft to lift itself out of the water, allowing it to go faster, we will not want the nose of Aussie Invader 5R to create any real lift, if there is too much the car could flip. We need to keep a steady downward pressure on the nose and this will be achieved with the nose cones angled down design and adjustable canards (wing-lets) just behind the nose (not discussed here).

Swarbrick Yachts in Henderson, Western Australia have just completed the CNC profiling of our composite nose moulds. The design of this nose has taken several years to complete.

The extensive computational fluid dynamics (CFD) has been carried out by the Soto Group in NSW and Curtin University in Perth. Our completed nose will use Nuplex Composite products exclusively, is designed to minimise lifting moments and is capable of withstanding the extreme forces and heat generated by a car travelling at speeds up to mach 1.4 (450 metres per second).

The nose and supporting frame also need to be super strong, otherwise the extreme forces exerted on it could cause it to collapse or snap off completely and then the car and driver are really in the hands of the gods.

The first nose cone for Aussie Invader 5R has been taken from our recently finished mould and the project has taken a giant leap forward with the pre-production fibreglass nose cone being fitted to the car.

This version will be used to ascertain correct location of inspection hatches, fixings and the support frame. The inner wheel clearances and the anticipated debris from the front wheels will also pose a challenge and need be taken into account when modifying the mould prior to a carbon fibre nose being produced.

There may be a need for several nose designs and only testing and load sensing monitors will tell us if the nose is performing correctly. This is made all the harder with the cars mass and centre of gravity changing during a run. The mass change is significant with the car using up to 2.8 tonnes of propellant during a 1,000 mph (1,600+ km/h) run in around 20 seconds.